QI® Services

Information for professionals

Linde Healthcare has developed and performs several services and solutions

for safe and secure delivery of medical gases to patients in hospitals and healthcare facilities.

Innovating solutions in medical gas management

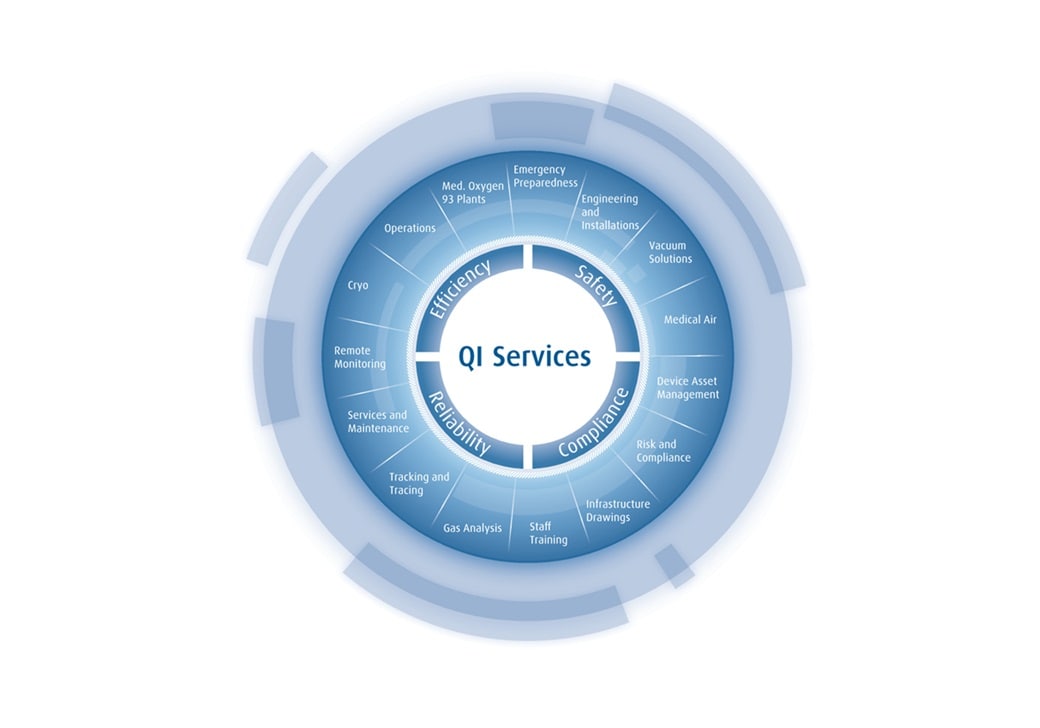

QI® stands for quality improvement. More than that, it is a view on the whole of your medical gas system and processes, bringing them up to best practice standards for quality as well as safety, reliability and efficiency.

QI® Services

With our broad QI® Services portfolio, Linde Healthcare can help you meet the considerable challenges of compliance and safety in today’s

healthcare environment. At the same time, we provide balanced insight and flexible tools to improve efficiency and coordination of medical gases throughout your facility.

Download:

QI services brochure

QI® Services areas

QI® Training provides courses for handling oxygen, storage, safe work procedures, emergency actions for medical gas systems, and technical management.

Compliance and safety are a key focus of our training packages for hospital staff, as well as issues specific to effective medical gas management, operating policy, and maintenance of medical gas piping and gas supply systems as well as medical devices.

QI® Training programmes cover essentials such as safe procedures for the handling, storage and use of compressed

gas cylinders; safe working practices; and understanding of hazards associated with gases.

For medical and nursing staff, training typically covers the safe use, storage and handling of medical gases, and emergency actions for medical gas pipeline systems and cylinders.

Training courses are set up locally, and can comprise multiple modules designed to ensure the needs of a particular staff group are met. In addition, Linde Healthcare has

developed an e-learning solution, for some markets, to allow staff to complete their training about basic safety in their own time.

Ensure Your Hospital is a Safe Place. QI® Risk provides inspection or survey of healthcare facility gas supply system for compliance to standards, to identify safety, equipment and procedural risks, and give recommendations for risk management.

For an overall assessment of your facility from a medical gas perspective, QI® Risk provides an in-depth inspection of the gas supply system in accordance with International Standards;

recognised Best Operating Practice and the respective country-specific Regulations. Starting from a site audit which focuses on, among other issues, safety, product and operational risks, recommendations

are then consequently given for safety improvements, risk management and compliance to standards.

An extended service can include establishing operational policy, maintenance and cylinder storage specifications, updating of pipeline drawings, design advice for supply system improvements and contingency planning.

Identify risks - Linde Healthcare will survey the medical gas related equipment and conduct interviews with your staff, covering all of the areas referred to in regulatory guidelines, standard operating procedures

and best practice. The audit will point out areas of non-compliance and include identification of potential risks and shortcomings in the following areas:

- ● Level of patient risk.

- ● Bulk tank sizing and advice on safe location.

- ● Gas supply equipment capacity and condition.

- ● Distribution systems.

- ● Manual handling.

- ● Management systems and documentation: preventative maintenance effectiveness.

- ● Training needs analysis.

- ● Cylinder storage and signage.

- ● Provision of equipment and emergency backup.

- ● Emergency preparedness

- ● Documented risk analysis

Identifying the risks in your hospital is not enough. They then need to be documented, prioritised and incorporated into your hospital’s risk register. We are able to provide a qualified, impartial and

pragmatic view of risk in your systems, using our experience with supplying medical gases for over 50 years. We apply verified risk analysis methodology using our own database to ensure consistency.

Some common risks identified by comparison to regulatory guidance and best practice include:

- ● No or limited nurse/ancillary staff training.

- ● No designated nursing or medical officer for gases.

- ● Inadequate product/prohibition/warning signage and emergency notices.

- ● Medical gas piping drawings incomplete/out of date.

- ● Operational Policy incomplete/out of date.

- ● No clear control of contractor operations.

- ● Inadequate storage/segregation of full and empty cylinders.

- ● No knowledge of standards/compliance shortcomings.

- ● No cylinder management programme in place.

- ● No designated storage points at ward level.

- ● Indistinct MGPS (Medical Gas Pipeline System) specifications.

- ● No indication of plant and system flow rate capacities/demand characteristics.

- ● Authorised Person not identified or sufficiently authorised.

- ● No planned maintenance programme.

- ● Establishing an Operational Policy

International and national standards require that a detailed Operational Policy is in place at each hospital to ensure pharmaceutical quality gas delivery to patients. This requires that a policy is developed

specific to the hospital and based on a comprehensive compliance survey. The policy should be detailed enough to promote best practice procedures and information.

Elements would include but not be limited to system description overview and operation, management responsibilities, identification of stakeholders and respective responsibilities,

staff training requirements, operation of the permit to work system, normal and emergency operational procedures, specifications of supply plant and manifold log sheets.

QI® ACCURA/QI® Tracking and QI® Securesupply are hospital medical gas services to track cylinders

as well as managing onsite stock for better medical gas logistics.

Managing the supply of medical gases should be secure, effective and easy. Depending on the market, our services may include:

- ● QI® Tracking. Online web service - from receipt to user to cylinder return. QI® Tracking cylinder management is a straightforward service

that enables the hospital facility to follow and use information about the location and status of its gas cylinders throughout the healthcare facility.

This can help to, for example, reduce the number of lost cylinders, locate cylinders in an urgent recall situation, trace

cylinders from a given batch at a recall, optimise cylinder use, reduce the time spent on administration and itemise cost to different users in the hospital.

Generally, QI® Tracking services work via scanning of an identification tag or label for the collection and storage of traceability data. This data is fed into a computer database, via installed software or a web server. Hospital staff can easily access the information as needed to trace cylinders, check stock levels or optimize needed stock on ward level, etc.

The advantages of QI® Tracking go beyond traceability. You can assess cylinder utilisation and allocation from an economic and facilities management perspective. A range of automatically generated reports may include updated information on location, stock levels, cylinder rotation, expiration dates, lost cylinders, cylinder balance and safety. - ● QI® Securesupply: Remote monitoring of onsite stocks - QI® Securesupply is a surveillance and remote control solution designed to help the hospital pharmacist

or technician get information on and manage stock of central sources of medical gas. The automatic gas supply system is based on remote control and telemetry, could be both for the bulk gas supply as well as the cylinder supply situation.

When supply reaches pre-determined levels, an order process is started by an electronic signal and prompts information about needed delivery of cylinders or the refilling of the bulk tank at the hospital.

The service enables savings in time and resources for continuous monitoring and re-ordering and avoids inadvertent stock outs. The supply process is secure and hospitals achieve optimised medical gas logistics.

Right From the Very Beginning.

QI® Design covers advisory and detailed sizing and construction plans for medical gas pipeline systems to meet standards, regulations and hospital clinical requirements.

Now, more than ever, it is vital to have secure design and engineering solutions. With QI® Design, Linde Healthcare provides a range of services from the

complete provision of designs to the review and assessment of in-house or contractor proposals.

Design of medical gas pipeline systems is a detailed and skilled operation that must ensure the plans meet both current Standards and Regulations

as well as the clinical needs of the hospital. Design would cover calculation of flow rates, pipe sizing, plant sizing, manifold and cylinder storeroom

sizing, ward based storage and recommendations for vessel positioning and locating of cylinder stores.

QI® Design services can work either from an outline brief to produce a full set of detailed drawings, or can be a consultancy or advisory role with

respect to proposals made by others for new installations or enlargements, new plant, layout changes etc. including formal assessment of contractor submissions.

At the Core of Your Pipework & Supply Systems.

QI Engineering offers expertise for new or refurbished medical gas system installation, commissioning, and start-up in the healthcare facility, in compliance to standards and regulations.

QI® Engineering offers you high quality hands-on expertise for the installation, testing, commissioning,

and start-up of customer-owned medical gas supply systems in hospitals, whether these are a new build or a refurbishment/enlargement.

Trained and experienced fitters, backed by Linde engineering resources, ensure that all installations are carried out strictly in

accordance with international and national Standards. Full certification is provided following each installation.

The service includes not only the installation, but also the full suite of tests, checks, procedures, and analyses as detailed in the relevant Standards and Regulations for the country.

QI® Engineering can also provide experts to carry out independent commissioning of new or modified medical gas pipeline systems, management of planned hospital shutdowns,

or onsite management of other contractors. Depending on the territory, the provision of Authorised Person (AP) services may also be available.

A Proactive Approach. QI® Maintenance helps to improve equipment and system reliability and efficiency, from supply to point-of-use.

Maintenance services ensure that the performance and reliability of gas equipment and pipelines are utmost in safety and compliance to guidelines. As nothing is more costly and frustrating

than unexpected interruptions, our services can help you to eliminate equipment deficiencies and improve cost efficiency through the reduction of gas consumption and a number of interruptions.

QI® Maintenance: Onsite maintenance both routine and response.

For hospital-owned installations, QI® Maintenance agreements are intended to safeguard the spectrum of equipment and systems between the supply unit and point-of-use. The services would

include regular inspection visits, emergency call outs by a trained service technician, repairs, or

periodic testing. Tailor-made solutions can also include comprehensive analysis, personnel training, control of failure risk, advice on compliance issues and assistance with any database updates.

QI® Maintenance ensures the installations meet the requirements of international Standards regarding specified intervals between services or can be used to monitor and control the

work of other contractors to ensure these meet the relevant Standards. Linde Healthcare can also provide rapid response solutions for emergencies in critical care areas.

QI® Point Analysis includes sampling and analysis of the quality of medical gases flowing through hospital pipelines to outlet, as to standards compliance and hospital safety.

QI® Point Analysis: Gas analyses ensure quality and safeguards patient safety.

Linde Healthcare boasts several years' experience carrying out gas analyses on behalf of the hospital sector and

pharmaceuticals industry. QI® Point Analysis samples and analyses the quality of the medical gases flowing through hospital pipelines to the gas outlet itself.

We provide a wide range of analyses, including medicinal air, medicinal oxygen, carbon dioxide (medical device) and medicinal nitrous oxide. All analyses

performed comply with current standards, including the European Pharmacopoeia (Ph.Eur), the Swedish Pharmaceutical Standard (SLS) and SIS HB 370.

We also handle analyses of non-medical gases, including a selection of speciality gases. It is necessary to perform gas analysis when installing a new central gas system,

following maintenance of a pipeline system or as a routine quality inspection.

The analysis service includes sampling, analysis and reporting, and sampling is always performed by Linde Healthcare's certified team.

Analysis vessels are always cleaned, inspected, and released by the laboratory before being used, and filled vessels are returned by our staff to the

laboratory for analysis in accordance with applicable standards. All procedures are fully documented in our quality system. The analysis report is subsequently issued to the client no later than 10 days after the

vessel reaches the laboratory. Where results deviate in relation to standard values, you will be contacted no later than 24 hours after this was detected. All analysis reports are archived for 10 years.

With our extensive knowledge of gases and gas analysis, we can advise on how, where and when samples should be taken. We have excellent insight into all relevant standards, and our laboratory is audited regularly.

QI® Medair (medical air, AMS) and QI® Medvac (medical vacuum, VMS) include services from design, supply and installation of medical oxygen supply to operation and maintenance of equipment, up to standards.

With QI® Medair (Medical Air, AMS) and QI® Medvac (Medical Vacuum, VMS), we provide services from design, supply and install to full provision of onsite plants.

All plant installs are fully compliant with international Standards and include three independent sources of air or vacuum. Linde Healthcare has many years of experience

operating such plants and longstanding relationships with leading component manufactures ensuring systems that are reliable, proven, and robust.

We handle the specification, sizing, design, installation, implementation, operation, and maintenance of the equipment as well as providing frequent analysis to ensure

compliance with GMP standards. With Medical Air we can also supply “Synthetic Air” installations either as the prime source or as backup to the compressors.

Depending on your area, we offer numerous business models from all-inclusive monthly fees for point-of-use air and vacuum provision to on call maintenance programmes.

An additional service may include dedicated supply to critical care areas in case of supply disruption in the regular network.

QI® Cryostorage services offers cryogenic liquid nitrogen storage facilities, equipment, supply, refilling and monitoring services for IVF, stem cells and clinical research.

Nitrogen (Medical device) is currently not available. For additional information please contact us by calling or e-mailing.

Secure cryogenic storage is essential today, for IVF, for stem cells, for clinical research and many more applications. With our advanced range of liquid nitrogen storage equipment, we can offer safe storage solutions on your own site and at Linde central facilities.

24/7 monitoring is key to ensure stored material is always maintained at the correct temperature. With QI® Cryostorage services, we offer a complete service from supply and delivery of liquid nitrogen to continuous monitoring, as well as maximum security offsite storage.

The onsite service encompasses supply of advanced design storage vessels, monitoring and tracking of all key parameters from our control centre, and routine supply and refilling of liquid nitrogen. Both purchase and leasing options are available.

In addition to installing and operating storage on customer sites we also offer secure off site storage of reference, archival and unique samples at our own facilities. These are highly secure locations with guaranteed supply of liquid

nitrogen, sometimes from adjacent production plants with 24/7 onsite operation. All aspects of storage are managed by highly

trained Linde engineers, and some of our specialised monitoring systems enable customers to view the condition of their material at any time via web portals. A collection and delivery service may also be available.

- QI® Training

- QI® Risk

- QI® ACCURA /QI® Tracking

- QI® Design

- QI® Engineering

- QI® Maintenance

- QI® Point Analysis

- QI® Medvac/Medair

- QI® Cryostorage

QI® Training

QI® Training provides courses for handling oxygen, storage, safe work procedures, emergency actions for medical gas systems, and technical management.

Compliance and safety are a key focus of our training packages for hospital staff, as well as issues specific to effective medical gas management, operating policy, and maintenance of medical gas piping and gas supply systems as well as medical devices.

QI® Training programmes cover essentials such as safe procedures for the handling, storage and use of compressed gas cylinders; safe working practices; and understanding of hazards associated with gases.

For medical and nursing staff, training typically covers the safe use, storage and handling of medical gases, and emergency actions for medical gas pipeline systems and cylinders.

Training courses are set up locally, and can comprise multiple modules designed to ensure the needs of a particular staff group are met. In addition,

Linde Healthcare has developed an e-learning solution, for some markets, to allow staff to complete their training about basic safety in their own time.

Downloads

Downloads

| Product datasheets & brochures | |

|---|---|