Different processes to achieve the best welding result

We provide end-to-end solutions to meet all of your individual welding related process needs from brazing in high temperatures to flame spraying to improve the surface’s resistance to corrosion.

Related areas

In both brazing and soldering, the solder is added in between the surfaces to be joined through capillary action.

In soldering the working temperature is below 450 °C and it is suited for welding copper and copper alloys, zinc,

steel aluminium and aluminium alloys. In brazing, the working temperature is between 450 °C–1000 °C and

well-suited for most metals.

Brazing is used, for example, for welding copper pipes in the production of bathroom fixtures and for fastening

pieces of hard metal to saw blades and drill bits. Soldering provides joints of high quality and high surface

finish. Soldering does not involve the same high working temperature as welding, which gives rise to less problems

with deformations.

Flame heating means local heating preparatory to hot forming, e.g. bending of pipes, necking of distributors,

dishing of vessel bottoms, or for preheating and reheating in welding and flame cutting.

There is a direct relationship between flow velocity and flame propagation rate. The higher the flame propagation

rate, the higher the flow velocity can be set. The higher the flow velocity, the higher the gas volume combusted

per unit of time. The more gas is combused, the higher the concentration of heat released.

Gouging is used in joint preparation and for removal of defective welds. It is similar to gas cutting. The

oxy-fuel gas flame heats up the piece to be worked to ignition temperature and the cutting oxygen jet combusts and

carries away the molten metal. In gas cutting the cutting oxygen beam is directed at a right-angle towards the

work-piece, while in gouging the oxygen beam is almost parallel with the surface of the piece to be worked.

An oxy-fuel gas flame can also be used in flame cleaning to clean surfaces from rust, mill scale, paint, grease

and dust. In gouging and flame cleaning various fuel gases are used together with oxygen. By using ODOROX®

(odorized oxygen) you can minimize the risk of fire and explosion which is always associated with fuel gases. The

smell warns of gas leaks in good time.

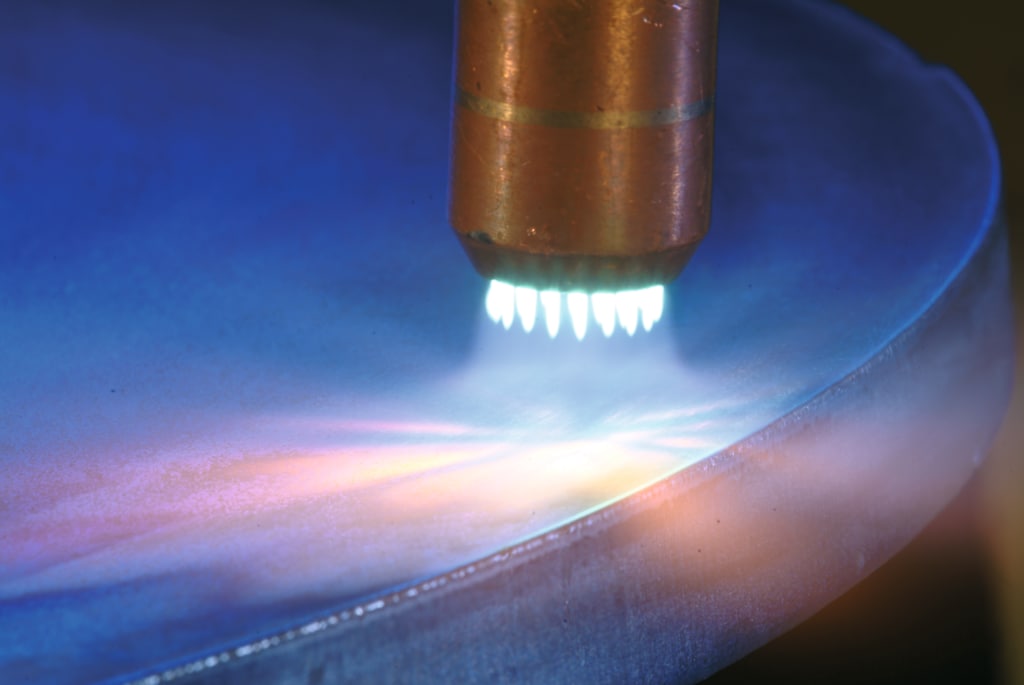

When spraying, the additive material, which can be in the form of powder, wire or sticks, is heated to melting

temperature or a practically melted condition. The heated material is finely distributed and sprayed by means of a

gas flow towards the surface of the piece (the substrate) where it fastens and solidifies. The sprayed surface can

be used as is or worked to the correct dimensions.

It is often a component’s surface that limits the life-time since it is exposed to wear, corrosion and/or high

temperature. Flame spraying with the correct additive material can improve the surface’s resistance to corrosion,

wear and high temperatures. You can achieve surfaces with high or low friction or alter the surface’s

conductivity.

Welding and cutting create tensions in the material that can lead to undesirable deformations. If those

deformations cannot be accepted, the piece must be straightened. Flame straightening is often a suitable method,

carried out by rapidly heating the construction or piece locally. When the material cools down it will shrink,

correcting the deformation. The method is suitable for steel, nickel, copper, brass, aluminium and titanium.

Even though different fuel gases can be used for heating, acetylene is the best choice since it provides the

hottest and most concentrated flame as well as the fastest heating. By using ODOROX® (odorized oxygen) you can

minimize the risk of fire and explosion which is associated with fuel gases.

Flame cleaning with acetylene is used wherever clean sheet metal surfaces are required for further processing. Flame cleaned surfaces ensure excellent adhesion of paint and coatings. Thereby, corrosion resistance is also improved. Flame cleaning procedures are also used for thermal treatment of concrete and natural stone surfaces. Also old paint and coatings, oil contamination, and abraded rubber can be removed in an environmentally friendly way. The concrete thus exposed gives optimal adhesion for synthetic resin coatings.

- Brazing and soldering

- Flame heating

- Gouging

- Thermal spraying

- Flame straightening

- Flame cleaning

Brazing and soldering

In both brazing and soldering, the solder is added in between the surfaces to be joined through capillary

action. In soldering the working temperature is below 450 °C and it is suited for welding copper and copper

alloys, zinc, steel aluminium and aluminium alloys. In brazing, the working temperature is between 450 °C–1000

°C and well-suited for most metals.

Brazing is used, for example, for welding copper pipes in the production of bathroom fixtures and for fastening

pieces of hard metal to saw blades and drill bits. Soldering provides joints of high quality and high surface

finish. Soldering does not involve the same high working temperature as welding, which gives rise to less

problems with deformations.