Dry Ice Cleaning

In conventional cleaning methods, powerful solvents are needed, which are dangerous because they are toxic and can easily ignite. Long downtime due to solvents presents additional challenges. By using dry ice (solid carbon dioxide), the user is freed from most of these problems and also gains significant benefits. The cleaning element (dry ice pellets) is extremely soft, so it does not scratch, wear or damage even delicate surfaces.

The most significant advantage of cryocleaning with dry ice snow is the possibility of dry cleaning. Because carbon dioxide is dry and does not leave any cleaning residues, no time-consuming drying processes are needed after cleaning. This leads to lower usage costs. There are also savings because there are no disposal costs as dry ice quickly turns from solid to gas and evaporates.

Other characteristics:

→ Dry ice pellets do not contain water.

→ The temperature of the pellets is -78 °C.

→ Carbon dioxide is considered non-toxic. Exposure limits must be observed.

→ Carbon dioxide usually behaves like an inert gas. This means that it does not react chemically with its environment.

→ It is also non-flammable.

Did you know?

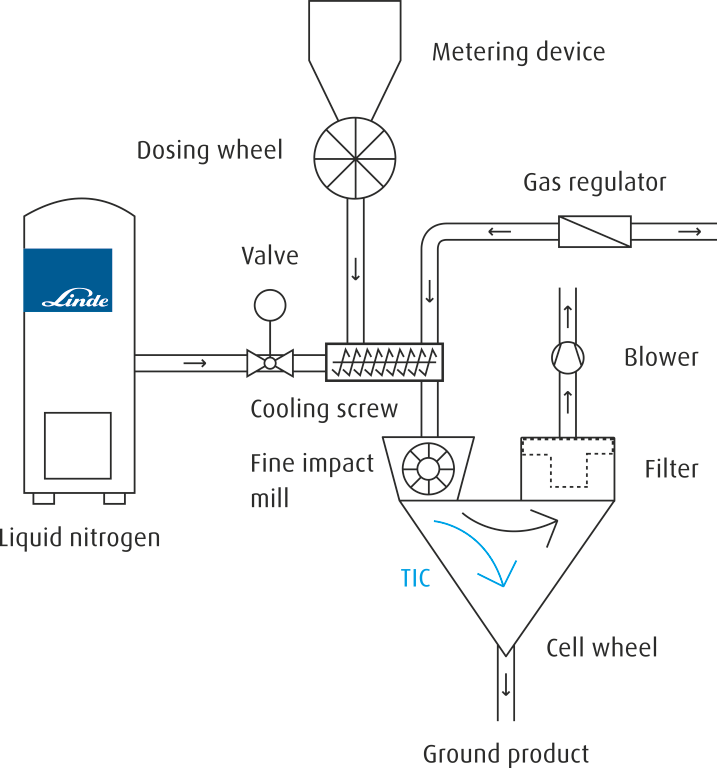

● To produce rubber materials such as crumb rubber, it is necessary to reduce the size of rubber waste or chips. This is done with a technique called cryogenic grinding. In cryogenic treatment, liquid nitrogen (-196 °C) is used to freeze the tire chips before size reduction. The rubber is immersed in liquid nitrogen to lower the temperature of the tire chips. The chilled rubber mixture is then ground in an impact-type reduction apparatus.

● Typical applications for dry ice cleaning include dirt removal, such as:

Oils

Greases

Paints

Waxy substances

Anti-corrosion coatings

Adhesives

Resins

Production residues

Synthetic materials

Foodstuffs

Grinding

Cryogens can be an effective way to reduce the size of materials that cannot be ground under normal conditions. Many materials that are elastic at ambient temperature become brittle and glassy at low temperatures. As a result, these materials can be crushed by impact or cutting. This type of grinding can also be used to create unusually shaped or sized particles.

Cryo grinding is suitable for various materials. For example, sticky or oily materials can often be solidified and ground. Heat-sensitive products can be processed at such a temperature that they can be crushed without breaking or melting. In addition, a cryogenic shock can loosen multi-component materials, such as chrome-plated ABS plastic. Spices can be ground without the loss of volatile oils and aromas, preserving and enhancing their quality.

Liquid Nitrogen

The most commonly accepted cold grinding medium is liquid nitrogen (-196 °C). Unlike carbon dioxide, liquid nitrogen (LIN) does not go through a solid phase but goes directly into a gas state. Therefore, LIN can be sprayed directly into a grinding mill. During the process of converting from a gas phase, it causes a powerful cooling effect in the product. Solid carbon dioxide (also known as dry ice) or liquid carbon dioxide can also be used as a grinding coolant if temperatures do not need to be lower than -78 °C. We offer customized and targeted delivery concepts for cryo grinding equipment, ranging from gas feeding and storage systems to feeding lines through pressure and temperature monitoring solutions.

Buy products here

Downloads

Downloads

| Safety datasheets | Product datasheets and brochures |

|---|---|