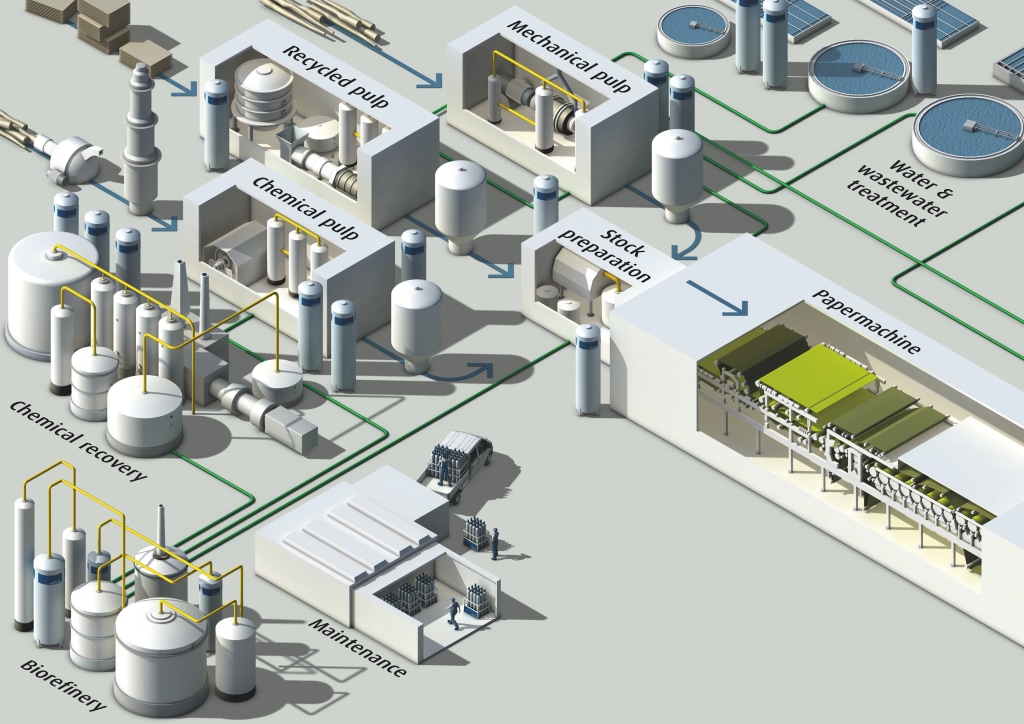

Process Optimization with gas applications in the manufacturing of pulp and paper

Many forest industry companies rely on Linde gas applications to optimize their processes. Carbon dioxide is used in pulp washing to increase capacity or improve washing results, especially in factories producing brown pulp. With the ACTICO application, pH is adjusted with carbon dioxide to the desired level in the wet end of the paper/board machine, which improves the functioning of chemicals such as adhesives. The ADALKA application is based on on-site sodium bicarbonate production and its use to increase alkalinity and stabilize the process.

Improving efficiency and sustainability

Many key players in the industry trust us to help increase capacity without the requirement for investment in new and larger equipment. We also help reduce dependence on hazardous chemicals, improve pulp washing efficiency, and stabilize pH, alkalinity, and calcium levels in papermaking. Our ACTICO® CO2 pulp washing solution can facilitate the transition from bleached pulp to unbleached pulp and help mills transition from paper to board. We also offer support for pulp and paper customers' water treatment, including cost-effective wastewater treatment solutions such as SOLVOCARB® and SOLVOX® oxygenation solutions, which keep treated wastewater contamination levels safe and avoid non-compliance.